NET@PRO SUITE FOR THE RUBBER & PLASTICS INDUSTRY:

MANY NEEDS, ONE SOLUTION.

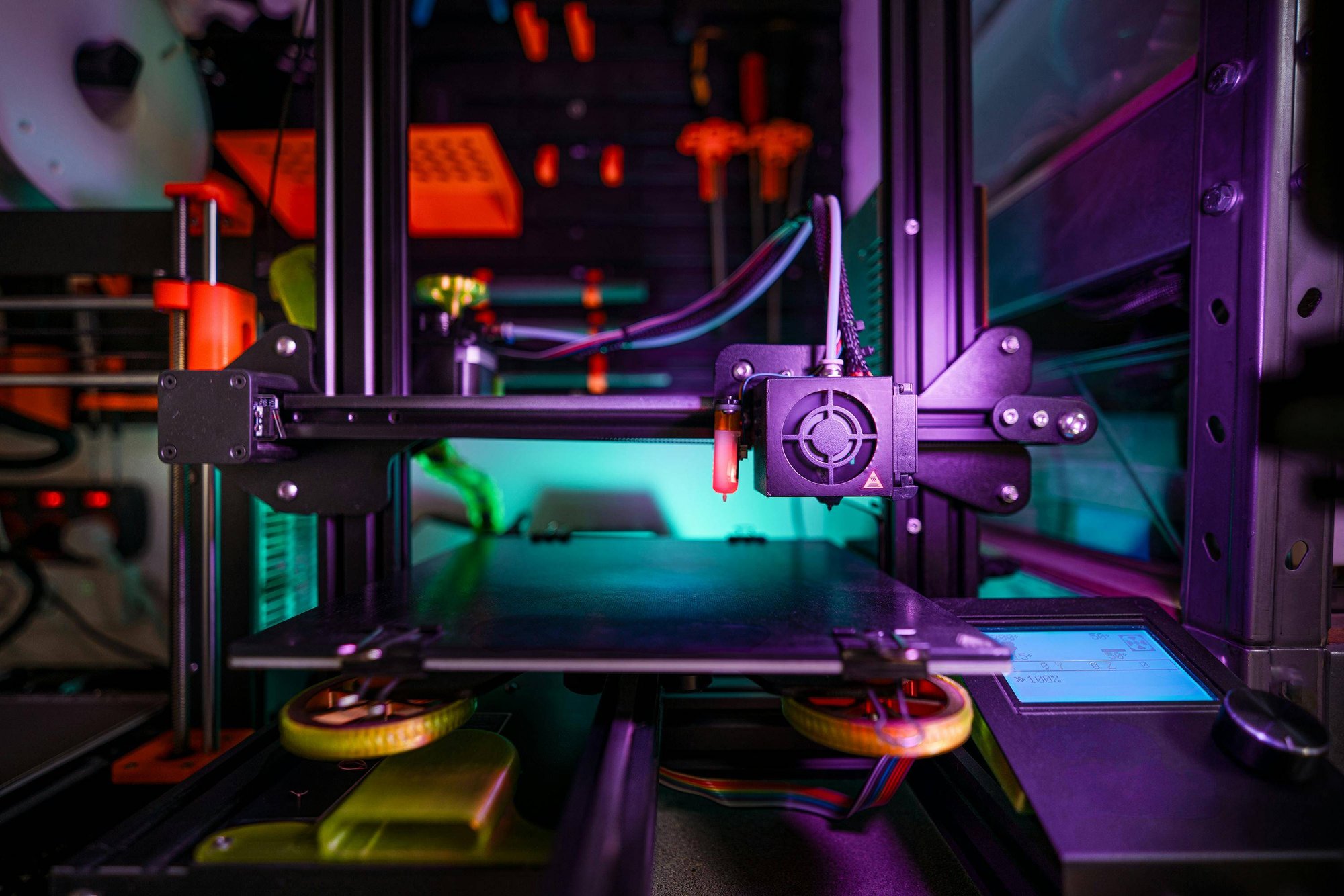

It eliminates waste and inefficiencies in molding processes. With NET@PRO, every production step-from injection molding to blow molding-is optimized for maximum operational efficiency.

MES ensures correct machine setup, reduces downtime and improves finished product quality, even in production lines with different materials and configurations. Automation, traceability and precision for an increasingly competitive industry.

Complete control of production

Traceability and quality assured

Optimization of equipment and resources

Flexibility for all types of molding

Digitize your molding process

NET@PRO is the MES solution designed for plastic and rubber molding companies that want to improve efficiency, quality and traceability while reducing waste and costs

NET@PRO SUITE.

.webp?width=2000&height=1332&name=Plastica_4%20(1).webp)

Qualitas in numbers

They chose Qualitas

Each success story is a tangible example of our commitment to ensuring maximum value for our clients.

Request information

The Qualitas specialist team is at your disposal for a free consultation and checkup to improve the productivity of your company with a demo of the MES NET@PRO software and the functional analysis of production flows.

Fill out the form or write to marketing@qualitas.it or call at

+39 0445 641844